.....................................................

Steam

boilers

......................................................

Accessories

Feeder units

.....................................................

Design

Selling

.....................................................

Company info

.....................................................

|

|

| Sanitary Hot Water SHW 30 |

|

|

|

The CARBOROBOT boilers capable to heat sanitary hot

water(SHW) with separate hot exchanger. The hot exchanger placed

direct on the side of the boiler. This hot exchanger work only close

of the boiler body, with distance from the boiler it is not work.

The hot exchanger have input for the cold pipe water and output

for the hot water, what we can use direct or for the buffer of hot

water. If we open the hot water tap the cold pipe water will flow

in the hot exchanger and the sensor will start the pump of hot exchanger.

This pump will run until the tap is open. When the tap we close,

the sensor will switch off the pump after some minutes(when the

input tube will grow hot from the boiler).

The special feature of this equipment when the boiler body is cold

the sensor will switch on the pump at that time also when the tap

of hot water is closed. The pump will run until the boiler temperature

will higher then switch off temperature of hot exchanger sensor.

This temperature adjustable in the box of hot exchanger. It is expedient

to regulate around 40°C to avoid the unwanted work of the pump.

If we use this type of hot exchanger than the regulation of the

boiler need to make depend to the water temperature of the boiler.

It's mean the regulation of the boiler not with the room thermostat,

(in this case the boiler can be regulary cool down bellow than 40°C).

The hot water reserve in the boiler is big. One Farmer 40kW boiler

with the heating water inside more than 1000kg. This hot mass can

serve several hundred litre 50-60°C DHW in a short time. The boiler

after falling of temperature of the heating water app. 10°C will

start automatically and the SHW source. In the practice one powerful

shower and one SHW tap in one time can operate. The hot exchanger

module can be dismounted for the cleaning. The cleaning period depend

to application time and the water hardness. We recommend to use

lime prevention systems. This hot exchanger unit separate can be

buy and possible to use for any CARBOROBOT boiler.

Heat capacity app. 30kW/h

Delta t. 40°C (60°C boiler temperature and 10°C pipe water temperature)

Flow through 12litre/min if water pipe pressure is 3 bar

|

Buffer accumlator

|

|

|

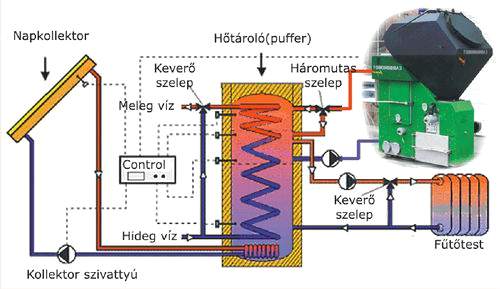

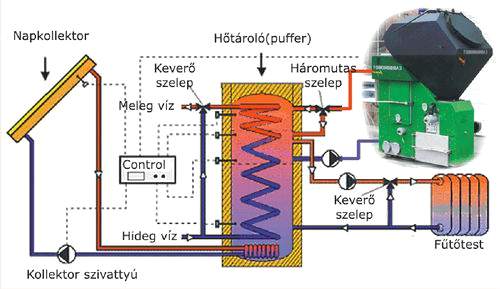

If we using firewood chamber frequently(more

hours every day )than for the CARBOROBOT Farmer need the

buffer accumlator.

If we usning firewood chamber only infrequent(1-2 hour

time on the week) than not necessary to use buffer accumulator.

For the CARBOROBOT types not necessary

install buffer accumlator, but if we build compose system with

solar than it is important part..

|

|

Compose heating system

|

|

|

|

|

|

|

Brazed plate heat exchanger

|

|

|

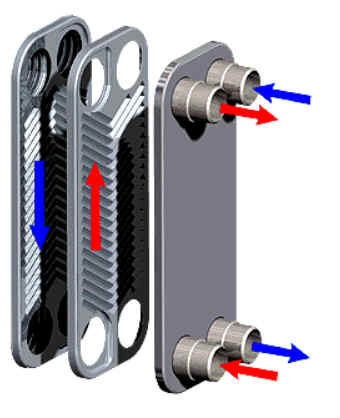

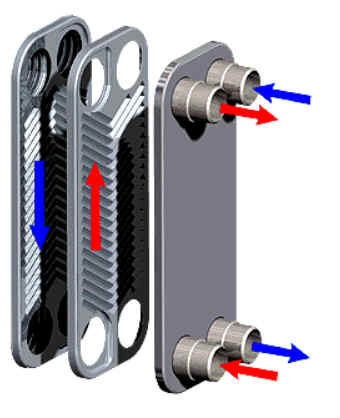

The Brazed Plate heat exchanger consists of either

25 or 50 multiple, thin, slightly-separated corrugated plates

that together form a very large relative surface area given the

volume of these heat exchangers.

The Outstanding Features:

Compact structure and easy installation

Light in weight

Small consumption of water

Outstanding Overall Heat Transfer Coefficient

Wide Variety of plate sizes and Patterns

Durability and

Stainless Steel

Low scaling coefficient

|

|

|

Plate heat exchanger

|

|

|

|

Another type of heat exchanger is the plate heat exchanger. One

is composed of multiple, thin, slightly-separated plates that have

very large surface areas and fluid flow passages for heat transfer.

This stacked-plate arrangement can be more effective, in a given

space, than the shell and tube heat exchanger. Advances in gasket

and brazing technology have made the plate-type heat exchanger increasingly

practical. In HVAC applications, large heat exchangers of this type

are called plate-and-frame; when used in open loops, these heat

exchangers are normally of the gasketed type to allow periodic disassembly,

cleaning, and inspection. There are many types of permanently-bonded

plate heat exchangers, such as dip-brazed and vacuum-brazed plate

varieties, and they are often specified for closed-loop applications

such as refrigeration. Plate heat exchangers also differ in the

types of plates that are used, and in the configurations of those

plates. Some plates may be stamped with "chevron" or other

patterns, where others may have machined fins and/or grooves.

|

|

|

|